Central Dust Collection System

- Share

Central Dust Collection System

Central dust collection system is widely used in multi-points of dust collection, for example,

A company has 3 welding tables and 2 polishing booths, A company should design the airflow suitable for 5 points.

B company has 3 tablet pressing machine and 3 screen machine, we should concern them to collect the dust together.

ACMAN analysis these systems and give three solutions below:

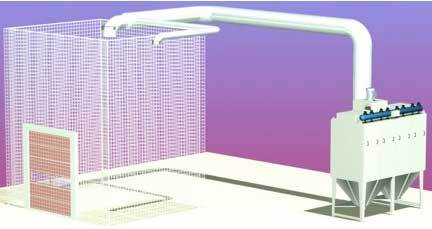

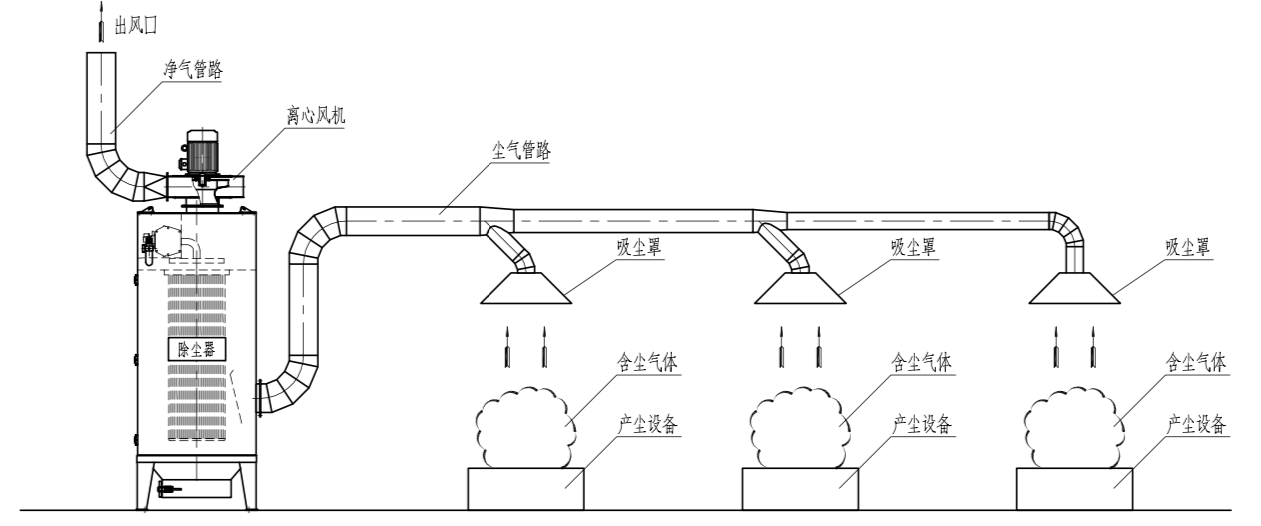

Multi-dust Extraction Hoods

This system is the most common one, which design the dust extraction hoods for multi-points. The dust in this condition is light, easy to raise which could be catched by the hoods.

The dust extraction hoods ends's air velocity is about 1-3m/min.

The pipe at the most distance hood from the dust collector should design from small to big. The pipe air velocity is about 20-23m/min to avoid the dust settling.

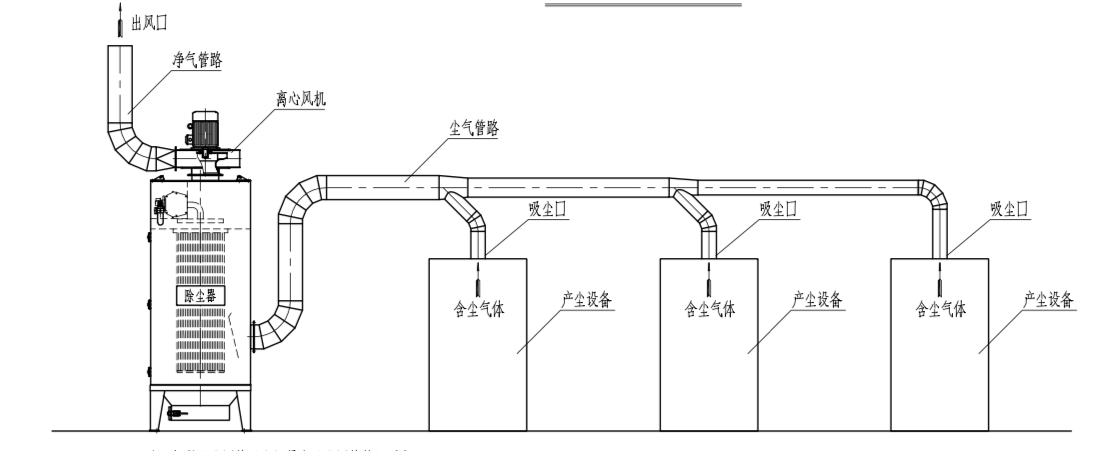

Multi-machineries Central Collection

Machinery central dust collection is differ from extraction hoods type. For example, packing machines or tablet press machines, the machine have dust extraction hole, but the hole is small, about 50-90mm, in these system, the branch pipe can not setting too long that could cause lots of pressures, the main tube should concern the pipe air velocity and pressure loss.

The same, The pipe at the most distance from the dust collector should design from small to big.

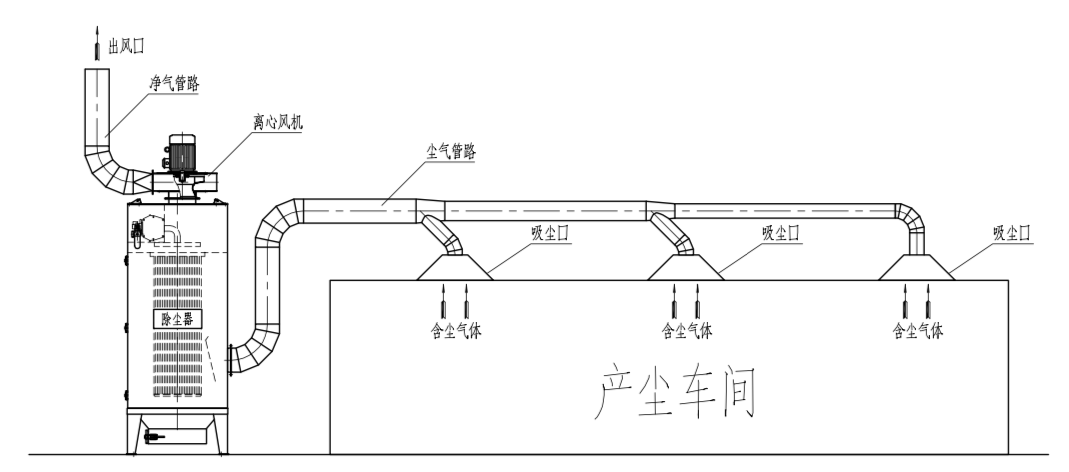

Whole Room Air Exchange-Multi Points

This air ventilation system usually is existed in HVAC system.

For the whole room purification, it only used for less dust concentration conditions. The airflow in this type is bigger than others.

For example, the room is 40m3, the exchange rate is 30times, the airflow is 1200m3/h...

Applications