Explosion Proof Dust Collector

- Share

Explosion Proof Dust Collector

The risk of dust explosions is ubiquitous in the production of many products. Once it explodes, the energy is huge and the destructive power is extremely strong. Risk assessment and quantitative risk analysis of dust should be carried out to reduce the risk of explosion.

An explosion requires five elements: combustibles, oxygen, media diffusion, ignition source and confined space. Are these elements present in your process flow? Combustibles can be particulate materials that diffuse in a cloud of particulates, or flammable gases or volatile chemicals that generate vapors. Oxygen is ubiquitous in most factory production processes. Combustion may be caused by open flames, welding arcs, spontaneous combustion, friction or sparks from static electricity. Most factory production processes have limited space. Once the above five elements exist at the same time, the factory will explode. The development of the explosion

An explosion is a rapidly propagating burn wave or detonation at low kilosonic speeds. The flame front moves slowly at first, but soon accelerates, creating a leading edge pressure or shock wave. Most industrial processes are not designed to withstand the pressures of explosions, so process equipment ruptures, releasing destructive high-pressure shock waves and flames. Subsequent damaging effects may include: A larger secondary explosion after the primary explosion disturbs the dust in the facility and a fire following the explosion.

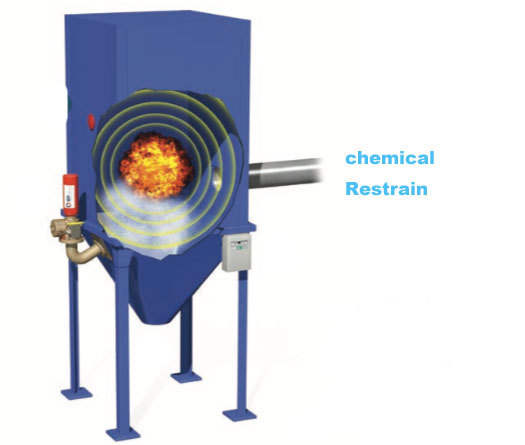

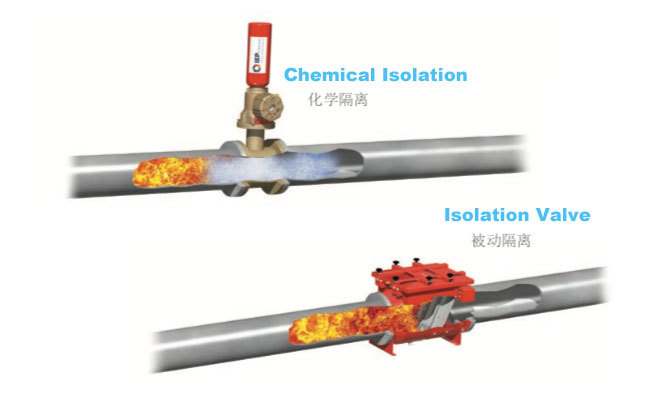

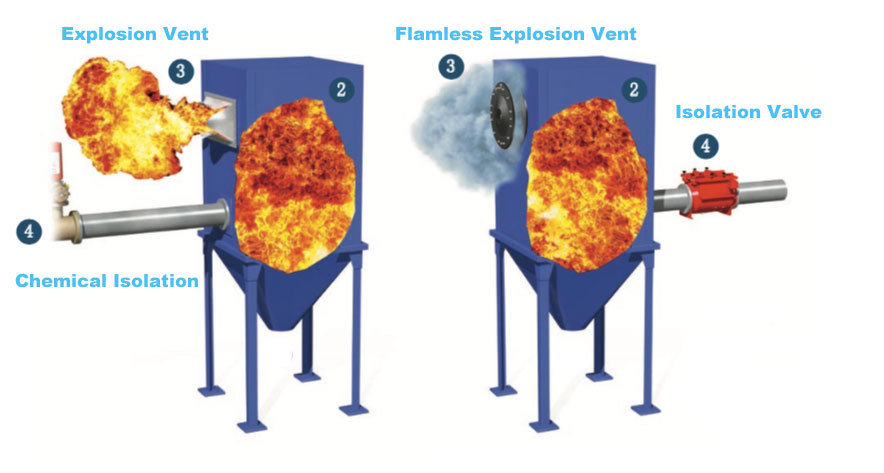

Usually, a combination of several technical measures is required to eliminate the safety hazards caused by deflagration. The techniques used in these measures can be divided into passive and active. Typical passive technologies use autonomous mechanical means and do not require external energy sources such as explosion vents and flameproofing

Devices are passive protection technology. Active functions require one or more energy sources, such as power, air, etc. Explosion suppression systems and spark detection systems are active prevention technologies used to detect and eliminate sources of ignition that could cause a fire or explosion.

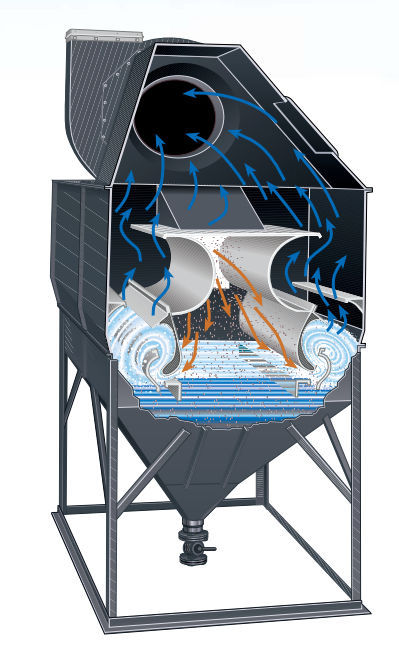

Wet Scrubber Dust Collector

Water Filtration

During operation, dust air passes through arc-shaped slot with high flow speed after it enters the purifying tank. Air stream in the slot turns sharply and blends forcefully with water, forming a water curtain at the slot exit that facilitates full contact between dust and water and enables dust to dissolve into water. Purified air is discharged out from water-retaining plate after moisture removed. By recycling water in the tank, Water consumption is therefore minimal, except for loss from evaporation. Water lost is replenished by automatic water refilling device to maintain water level. Sludge on the dust remover shall be cleaned regularly.

Wet Scrubber Solutions

1:Simple Construction allows Trouble Free Operation

No filter

2:Excellent Dust Collection Efficiency

8micron particles 100% collection with Single Scrubber

1micron particles 99% collection with Double Scrubber

3:Prevents Explosions and Fires

Uses water so no risk of fire or explosion

4:Pump Unnecessary

The gas itself forces water up eliminating the need for a pump