ACMAN Cyclone Dust Collector Industrial Powder Cyclone Separator Cyclone Dust Collection System

- Model

- XP-Series

Review

Description

ACMAN Cyclone Dust Collector Industrial Powder Cyclone Separator Cyclone Dust Collection System

How does the cyclone dust collector working?

Working Principle

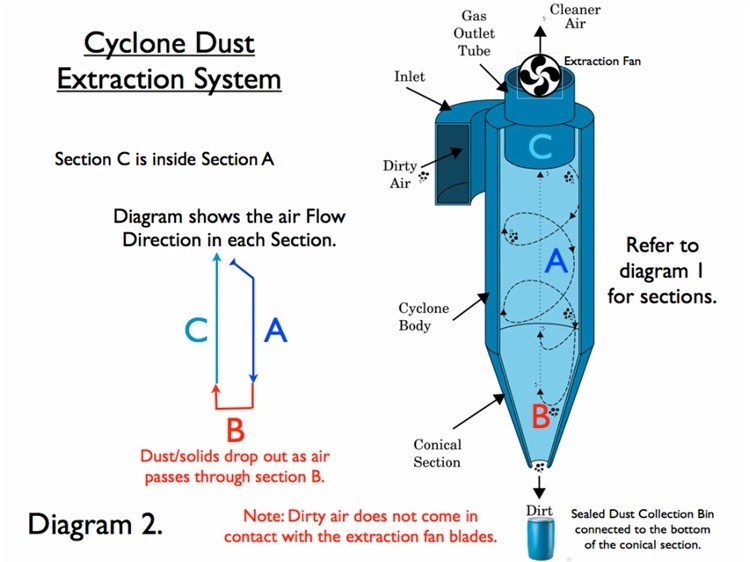

The dirt air come into the cyclone body from the side, so that the airflow could cause a tangential force or centrifugal force.

The A spiral path line is the air in the cyclone diagram. The big dust/heavy dust are fall down into the B dust bin because of the centrifugal force and crash on the internal face of the cyclone separator.

The light dust and the air are come to the C point by the centrifugal fan after the cyclone.

The efficiency is depending on the dust type, normally is about 70%-89%.

Advantage

1:Simple in structure, easy in maintenance

2:Low in cost, long service life

3:Good separation effect for coarse dust particles

4:Preliminary treatment for multi-stage dust removing

Applications

Pre-separator

The cyclone collector always plays a pre-separator role in the high concentration dust condition. For example: packaging, sandblasting, metal processing...

Heavy Dust Collection

Depending on cyclone dust extractor's advantage, cyclone always be used in the heavy dust collection, so the efficiency could about 89% for catching the dust.

Powder Recycle

Stainless steel cyclone are always applied in the powder recycle process, because the cyclone dust collection are easy for cleaning and washing.

Technical Parameter

|

Model

|

Airflow(m3/h) | Size(mm) |

Weight(Kg)

|

Resistance(Pa)

|

Velocity(m/s)

|

XP-200 | 370~590 | Φ200×940 | 37 | 880~2160 | 14~22 |

XP-300 | 840~1320 | Φ300×1360 | 51 | 880~2160 | 14~22 |

XP-400 | 1500~2340 | Φ400×1780 | 85 | 880~2160 | 14~22 |

XP-500 | 2340~3660 | Φ500×2200 | 132 | 880~2160 | 14~22 |

XP-600 | 3370~5290 | Φ600×2620 | 183 | 880~2160 | 14~22 |

XP-700 | 4600~7200 | Φ700×3030 | 252 | 880~2160 | 14~22 |

|

XP-800

|

5950~9350 | Φ800×3450 |

325

|

880~2160

|

14~22

|

|

XP-900

|

7650~11890 | Φ900×3870 |

400

|

880~2160

|

14~22

|

|

XP-1000

|

9340~14630 | Φ1000×4280 |

500

|

880~2160

|

14~22

|

Customer Application Case

Germany Customer

Our Germany had bought two cyclone for his small factory dust collection.

The dust type is the metal processing dust, this is a cleaver customer:

1: He installed the cyclone by himself, including the inlet hose, the structure, the dust discharge bag...

2: He installed a cartridge filter at the outlet of the cyclone as a second filtration stag, so that the dust collection efficiency will much higher.

This cyclone's airflow is about 2000m3/h, the material is carbon steel with powder coating, so the cyclone have long life span-It is corrosion resisting, anti-rusting....

CHOOSE ACMAN, CHOOSE SECURE!

Video