Pulse-jet Bag in Bag Out System Cartridge Filter BIBO Dust Collector Machine Unit For Toxic Dust

- Model

- AC.Safe2

Review

Description

Pulse-jet Bag in Bag Out System Cartridge Filter BIBO Dust Collector Machine Unit For Toxic Dust

Bag-in and bag-out filters appeared in the 1950s and 1960s, and are currently widely used in a variety of high-risk or high isolation requirements, such as: chemical and biological (CB) protection, chemical, biological and radiological ( CBR) protection, nuclear chemical, biological and chemical (NBC) protection, hospital isolation room, pharmaceutical equipment, microelectronics environment, food processing area, biological research, genetic and biotechnology laboratory, industrial processing discharge system, chemical processing equipment, animal Disease research laboratories, radioisotope processing equipment, nuclear power plants, strategic nuclear facilities, DOE equipment, military bases, etc.

How does this self-cleaning BIBO dust collector working

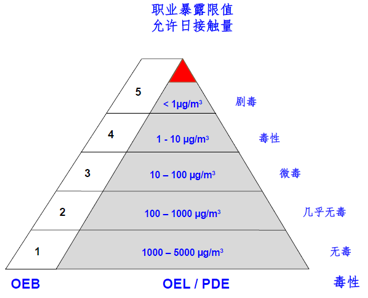

The equipment design refers to the leakage limit of the international OEB standard, and the overall design is in accordance with the control of the 1ug/m³ dust leakage rate and meets the requirements of the OEB5 standard

Bag-in-bag-out filter, namely Bag In Bag Out Filter, usually referred to as BIBO, is also known as a duct-type exhaust high-efficiency filter device. Since the filter has retained highly active or highly toxic harmful aerosols during the working process, it is necessary to ensure that the filter does not have any contact with the external environment during the replacement process.

The entire process of filter replacement is carried out in a sealed bag, so it is called bag entry Bag out the filter. Its use can effectively prevent the spread of harmful aerosols and avoid biological hazards to personnel and the environment. It is a filter device used in specific biological risk environments to remove harmful biological aerosols in the exhaust air. Generally, it has in-situ disinfection. And leak detection function, in the process of use, it needs to be equipped with biological sealing valve and other components.

Commonly used functional units include: Pre-filter, HEPA, HEGA, Precision ScanTest Sections, etc. The simplest filter unit only contains a high-efficiency particle filter. If there is no other filtering device before the air enters the bag into the bag and exits the filter, you need to configure a pre-filter to protect the high-efficiency particle filter. If the filtered gas has adsorption requirements, it is equipped with high-efficiency Gas adsorption filter; detection unit refers to automatic (or manual) fine scanning detection device.

Advantages

1:High safety of work:

With the bag in bag out(BIBO) Devices equipped in the dust collector, the cartridge filters exchanging work facing with dust side could reduce the risk of exposure of contaminated/ hazardous powders.

2:Differential pressure gauge:

Differential pressure gauge with screen and output signal point could test the pressure avoiding leakage of harmful dust like pharmaceutical active ingredients.

3:Small installation Area:

the side setting cartridge filters lower down the height of the bag-in and bag-out filters unit, the big filter area make the BIBO filter system became smaller.

4:Negative pressure design:

The AC.Safe2. filtering system unit could sustain -3000Pa pressure.

5: High dust collection performance:

The cartridge filter is polyester material with PTFE coating, reaching H10 standards.

The cartridge filter is polyester material with PTFE coating, reaching H10 standards.

The filter material could choose TORAY material to escalate the filter material standards.

6: Self-cleaning system

Self-cleaning air backflow system will prolong the cartridge filters, and make the pressure stable.

Self-cleaning air backflow system will prolong the cartridge filters, and make the pressure stable.

How to Change Cartridge filters?

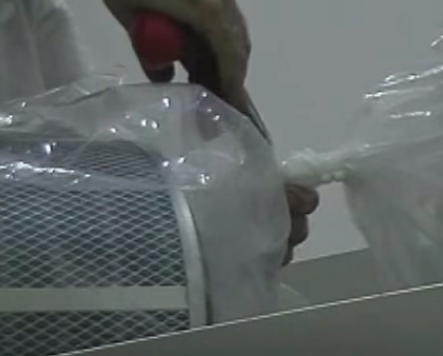

Step 1: Put on the safety bag

Step 2: pull out of the filter

Step 3: seal the waste filter and remove

Step 4: put on new bag with new filters

Step 5: remove the original bag, and pull into the new filter

Step 6: closed the door

Technical Parameters

|

Model. |

Air Flow (m3/h) | Sustain Pressure | Filter Area (m2) | Filter Size (mm) | Filter Quantity | Filter Material |

Temperature |

Efficiency |

Deashing Mode |

|

BIBO-F-1000 |

500-1000 | -4KPaG | 18.5 | 350*660 | 1 | Complex Fiber |

<120℃ |

F9 |

Pulse-jet |

|

BIBO-F-2000 |

2000 | -4KPaG | 37 | 350*660 | 2 | Complex Fiber |

<120℃ |

F9 |

Pulse-jet |

|

BIBO-F-4000 |

4000 | -4KPaG | 71 | 350*660 | 4 | Complex Fiber |

<120℃ |

F9 |

Pulse-jet |

Video

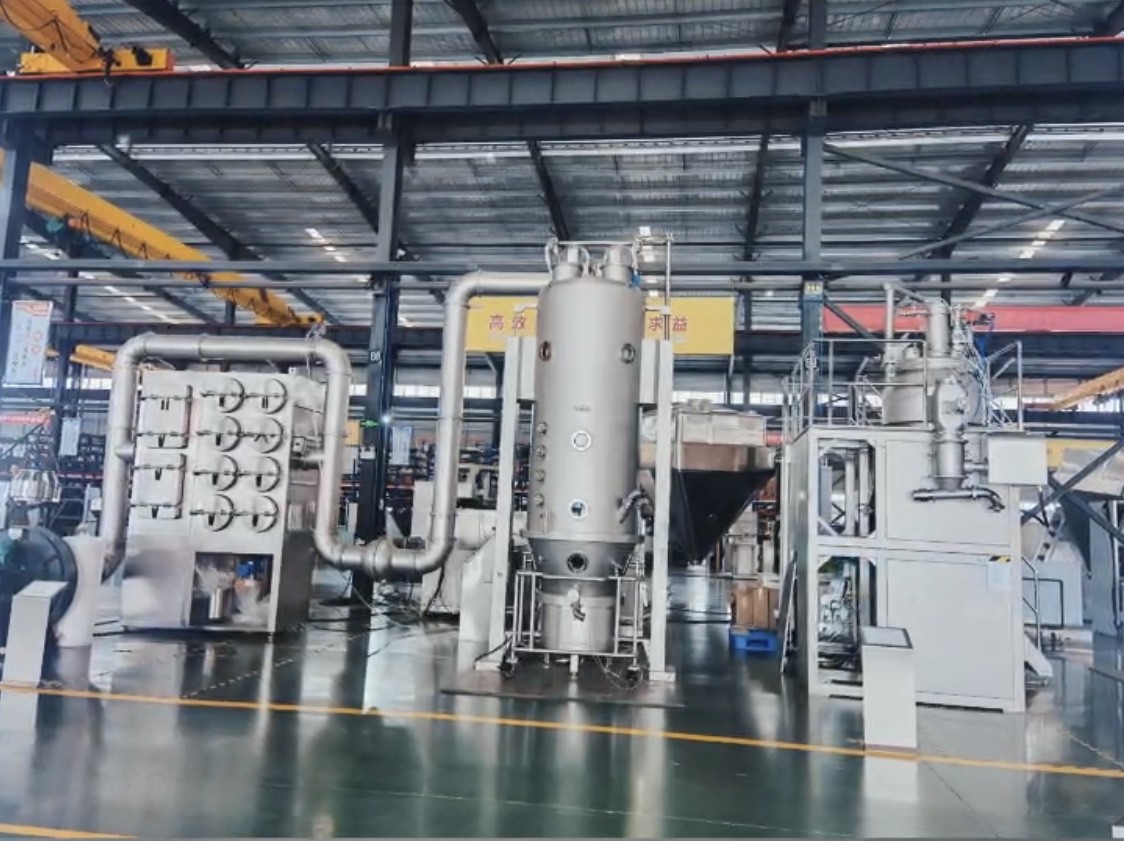

Fluidized bed BIBO filter unit