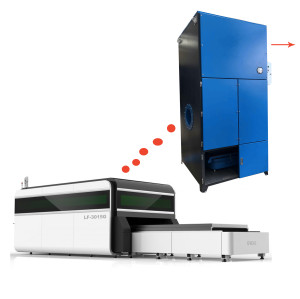

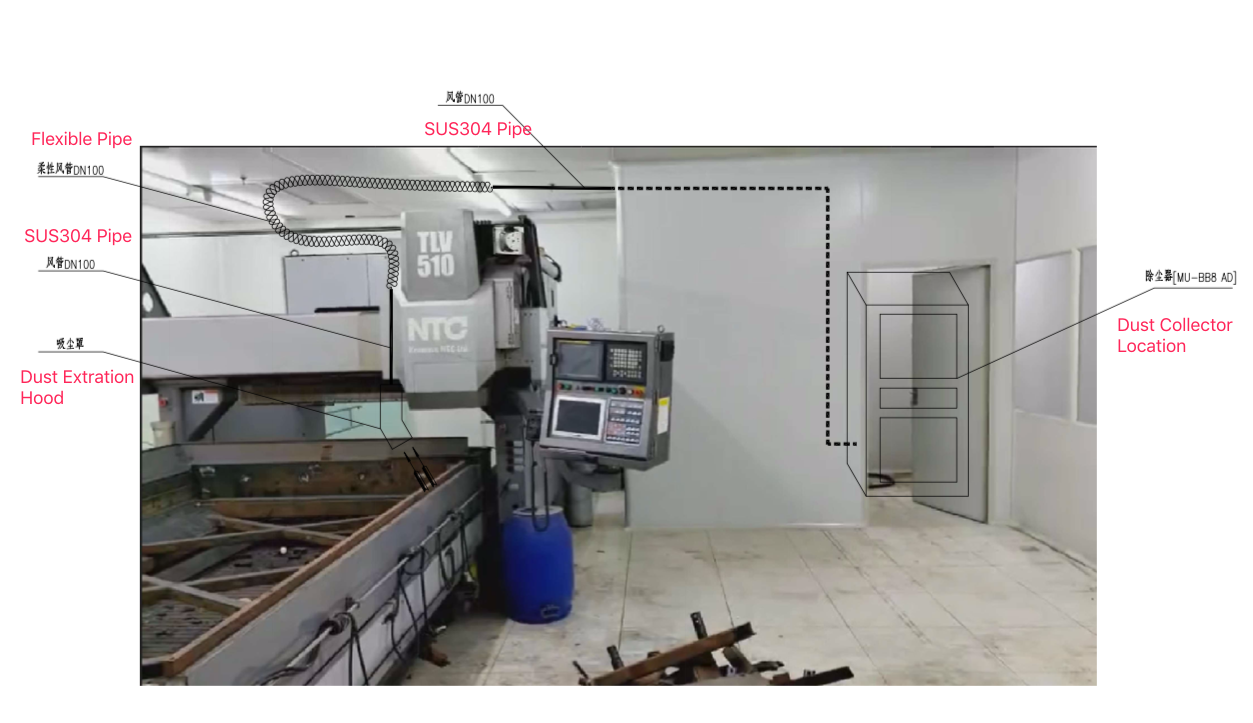

Semiconductor Silicon Laser Cutting Dust Extraction Solution for Komatsu TLV510 2D Laser Cutting Machine

- Model

- TOKA-100B-J

Review

Description

|

Model (B) |

Air volume (m³/h) | Filter Area (m³) | Fan pressure (Pa) |

Power (kw) |

Air Source (Mp) |

Sound (dB) |

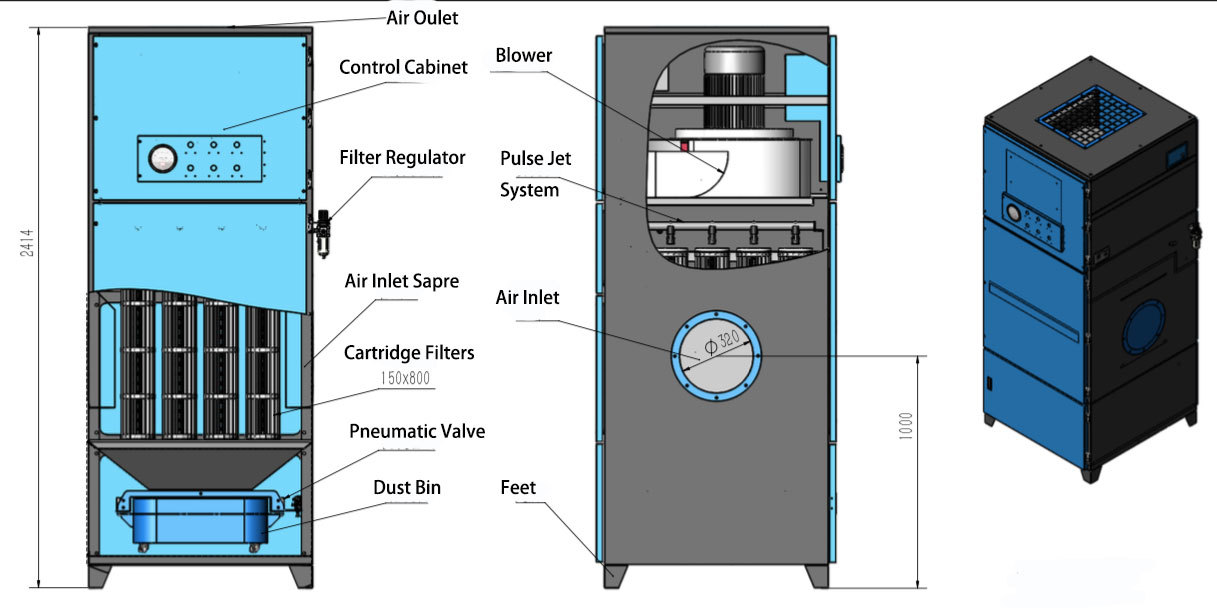

TOKA-8B-J | 500-900 | 12 | 1780 | 0.75 | 0.4-0.6 | 65 |

TOKA-10B-J | 900-1100 | 12 | 2040-1780 | 1.1 | 0.4-0.6 | 67 |

TOKA-15B-J | 1400-1600 | 18 | 2040-1780 | 1.5 | 0.4-0.6 | 70 |

TOKA-25B-J | 1688-2476 | 30 | 2150-1820 | 3 | 0.4-0.6 | 73 |

TOKA-30B-J | 2664-3405 | 30 | 2700-2200 | 4 | 0.4-0.6 | 73 |

TOKA-40B-J | 3786-4527 | 36 | 2700-2200 | 5.5 | 0.4-0.6 | 75 |

TOKA-60B-J | 4973-6457 | 48 | 2700-2200 | 7.5 | 0.4-0.6 | 75 |

|

TOKA-80B-J |

7081-8489 | 60 | 2700-2200 |

11 |

0.4-0.6 |

78 |

|

TOKA-100B-J |

8490-10455 | 75 | 2790-2020 |

15 |

0.4-0.6 |

80 |

|

TOKA-120B-J |

10400-13455 | 90 | 2790-2020 |

15 |

0.4-0.6 |

85 |

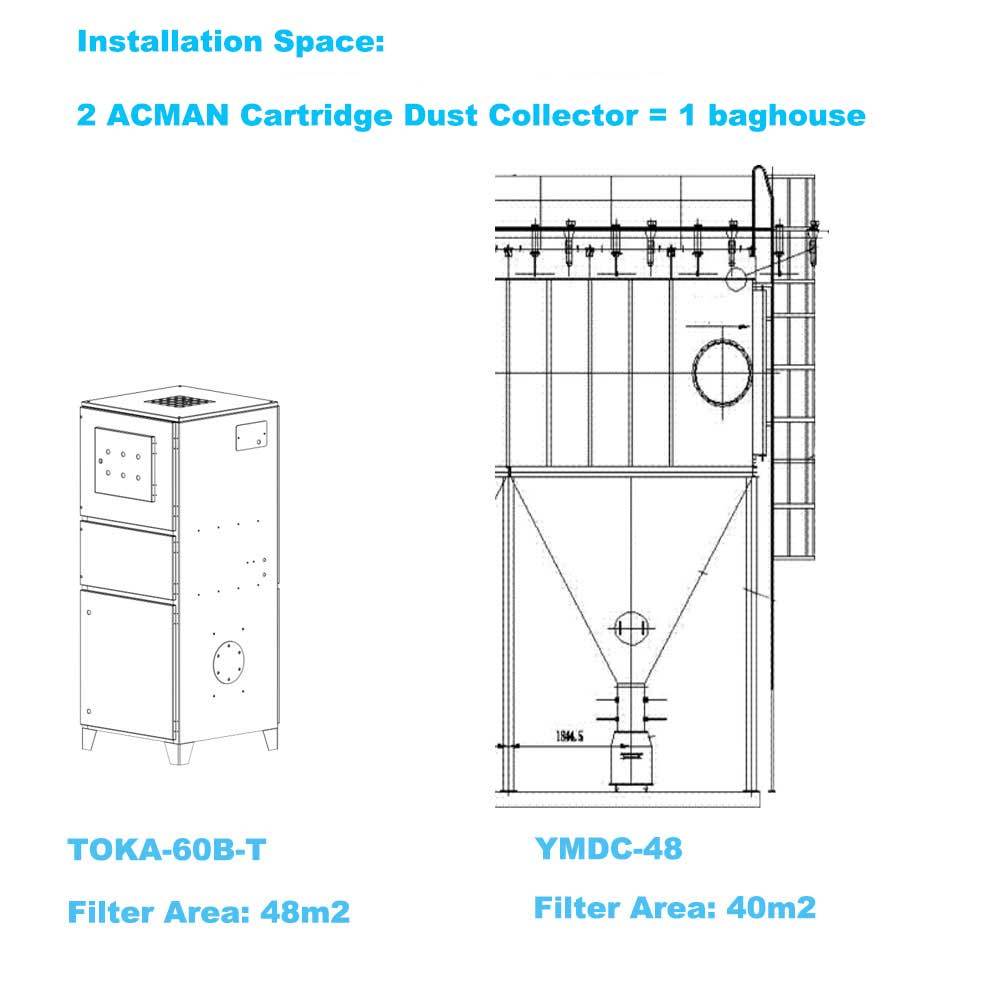

Item | Unit | ACMAN Pleated Filter Dust Collector | Bag House |

Airflow | m3/h | 10000 | 10000 |

First Investment | USD | Est 12000 | Est 21000 |

Fan Motor Power Consumption | USD/Y | 15kw/h*8h*365days | 15kw/h*8h*365days |

Air Compressor Power Consumption | USD/Y | 30Nm3/h | 90Nm3/h |

Filter Replacement | USD/Y | 1075 | 3320 |

Valve Replacement | USD/Y | 0 | 0 |

Maintenance Labor Cost | USD/Y | 300 | 1500 |

Downtime Cost | USD/Y | 2 Hours | 1 Days Est 2200+ |

3 Year Total Cost | USD | Est 39933 | Est 73669 |

6 Year Total Cost | USD | Est 67866 | Est 126336 |