KELLER L-CUT Type Dry Separator for Thermal Processes, LCUT Laser Fume Extractor

- Model

- KELLER VARIO ECO

Review

Description

KELLER L-CUT Type Dry Separator for Thermal Processes, LCUT Laser Fume Extractor

The L-CUT series is specially designed to collect and separate dust such as fine metallic oxide particles and fumes created by thermal processes such as joining, separation or surface treatment by laser, plasma or gases.

The compact filter unit has been specifically designed for the extraction of pollutants generated during thermal processes and surface machining.

Task

The L-CUT series has been specially developed for the collection of dust and fumes caused by thermal processes such as joining, separating, or surface treatment by laser, plasma or gases, to separate the finest of metal oxide particles. These units are compact and have a very low profile. Therefore, they can be installed in tight spaces. The spark pre-separator KSE is already integrated in the housing.

Applications

Effective and hazard-free filtration and separation can be separated safely and space-saving.

• Soldering

• Welding

• Thermal cutting

• Milling

• Grinding

• Engraving

Filter housing

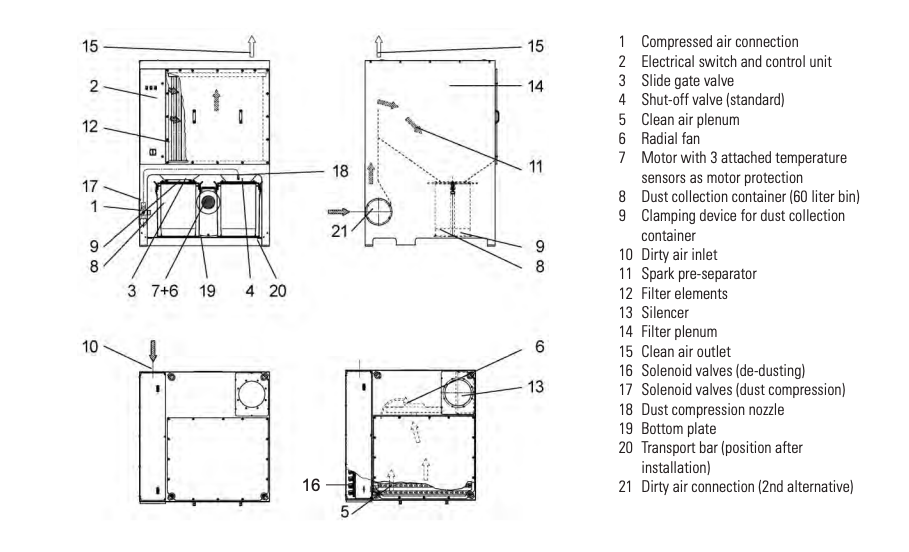

The housing is of welded design with a variable dirty air inlet opening. The integrated spark pre-separator protects the filter elements against damage that could be caused by coarse, potentially glowing particles. All relevant components, i.e. disposal bin, filter elements, motor-impeller section, solenoid valves, electrical switch and control system are accessible for servicing from the front

Functional Description

Dirty air flows through the dirty air inlet (10) into the spark pre-separator(11) where larger particles are separated. The collected dust can be emptied during operation by closing the manual slide gate. The separated dust is compressed in the disposal container (8) by means of a dust compression nozzle (18).

Air is deflected after the spark preseparator (11) which reduces speed

when the air contacts the filter elements (12). The dust particles settle

onto the surface of the filter elements, are cleaned off by compressed

air pulses and then fall into the two disposal containers.

The cleaned air flows through an intermediate level (5) into the clean air chamber where it is pulled through the fan (6) and then exits through the silencer (13).

Filter elements

Filter Cartridge

The cartridges consist of a starshaped folded filtering material

which is molded at the bottom and top into an end plate made of sheet steel. A basket of perforated metal plate or wire mesh is installed in the

clean air zone which ensures form stability.

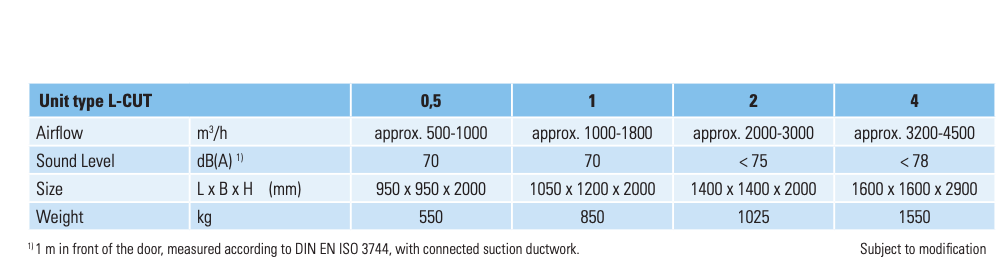

L CUT Type-Technical Data

Our Factory OEM photos for Keller Lufttechnik China

We could add Inert gas suppression protection system.