KELLER PT Type Air Filtration System, Keller Industrial Filtration Dust Collector

- Model

- KELLER PT Type

Review

Description

KELLER PT Type Air Filtration System, Keller Industrial Filtration Dust Collector

The PT Filter series is especially suitable for the separation of fine, free-flowing dust created by mechanical and thermal processes.

A special feature is the exchange of filter plates on the clean air side for easy maintenance, and reduced height for greater accessibility.

TASK

The PT filter series is most suitable for the separation of very fine dusts in numerous applications. Virtually all types of dust can be separated efficiently with these filters. Among its multiple applications are metals processing and finishing, as well as plastics processing, the chemical and pharmaceutical industries, or ceramics, stoneware and earthenware. The PT-Filter series is especially noteworthy in the dry separation of wet paint overspray. A useful feature is the filter plate exchange on the clean air side, which facilitates maintenance and reduces the overall height.

The PT filters have a modular design.This enables flexibility for different requirements, such as dust characteristics or the air flow to be extracted, etc. The sturdy and silent units enable trouble-free 24-hour operation at a continuous air flow rate.

Advantages

• Filter elements for a variety of material properties

• Modular design

• Disassembles into identical components

• Flexible installation options

• Simplified installation in hard-to-access area

• Access on the clean air side to the horizontally installed filter elements

• Vertically designed upward pressure relief is possible

• Suitable for explosion protection measures for indoor and outdoor

installations

Function

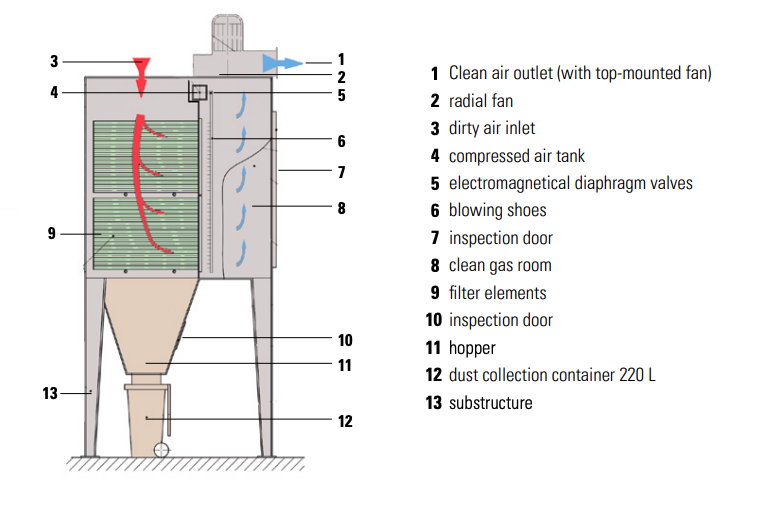

The dust-laden air flows through the dirty air inlet into the filter unit. A baffle plate slows down and deflects the dust particles to protect the filter elements from direct impact. An air down-flow is created between the filter elements, allowing the dust particles to drop. A fan in the clean air chamber draws the polluted air through the filter elements, depositing the dust particles onto the filter surface. Because the filter elements are cleaned continuously by compressed air pulses during operation, the air flow remains constant. The cleaned air exits through the top of the unit and in most cases can be re-circulated into the work area or vented outdoors. The separated dust falls into the dust collector containers.

Filter elements

Cartridges or plate filters are used, depending on the application, for enhanced separation efficiency and service life. All filter elements used are of high quality and easy to clean.

The filter elements are of high quality

and are available in a variety of materials. Each filter element is selected.

depending on the specific application, in order to achieve optimum filtration, separation efficiency, and length of service.

Cleaning the filter elements

The pulse cleaning cycle can be adjusted for each application by means of an integrated control unit. The air flow of the fan remains nearly constant. The cleaning operation is activated either by a differential pressure regulator while in operation, or by a programmable downtime cleaning cycle.

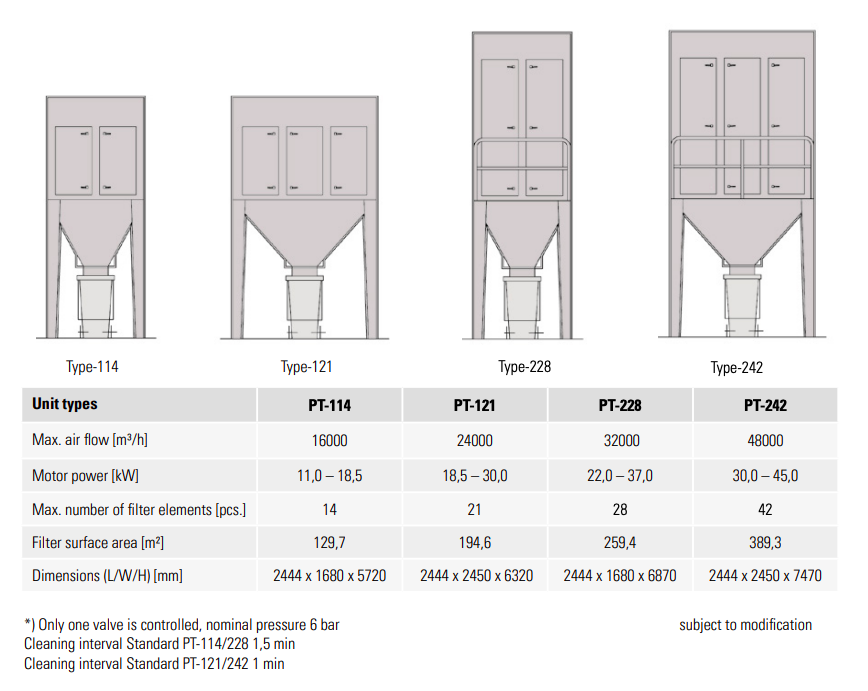

Technical Data for keller Vario Series dry separator

Our Factory OEM photos for Keller Lufttechnik China