Explosion Isolation Flap Valve, Explosion Proof Device, Passive Flap Style Isolation Valve for Dust Explosion

- Model

- AFV Explosion Isolation Flap Valve

Review

Description

Explosion Isolation Flap Valve, Explosion Proof Device, Passive Flap Style Isolation Valve for Dust Explosion

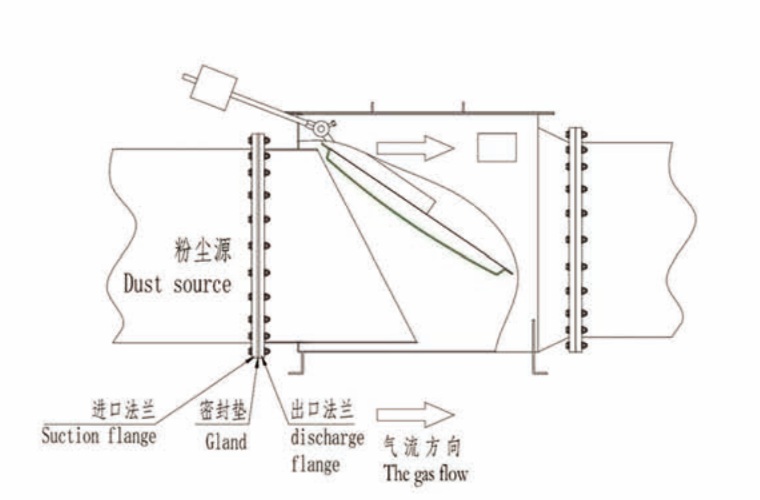

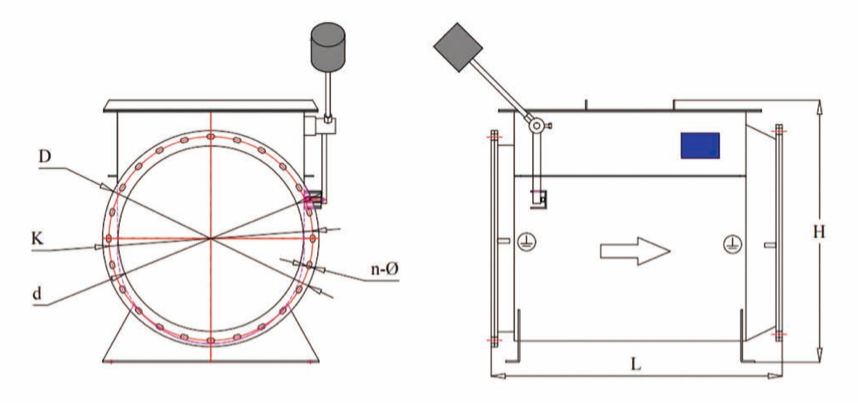

Passive flap style isolation valve-When a dust explosion begins to propagate down a pipeline the flap valve automatically closes from the pressure of the explosion. The flap valve remains shut and is designed to prevent any flame from further propagation. Unique to the AFV explosion isolation valve is a flap that is designed to stay open during normal operation. Typical flap valves rely on the flow of air in a pipe to lift up the flap. The AFV explosion isolation valve is able to offer lower pressure drops across the valve compared to other valves by featuring a normally open flap. Additional features include an integrated sensor to signal when the flap is shut, a variety of sizes to fit any application, and is available in both stainless or carbon steel designs.

Passive Explosion Isolation Barriers Advantages

1: Passive Explosion Isolation for Collector Inlet Ducts

2: Lower Cost Alternative to High-Speed Valves or Chemical Isolation

3: Sensors improve reliability, reduce inspection frequency

4: Third-Party Performance-Based Approvals per requirements

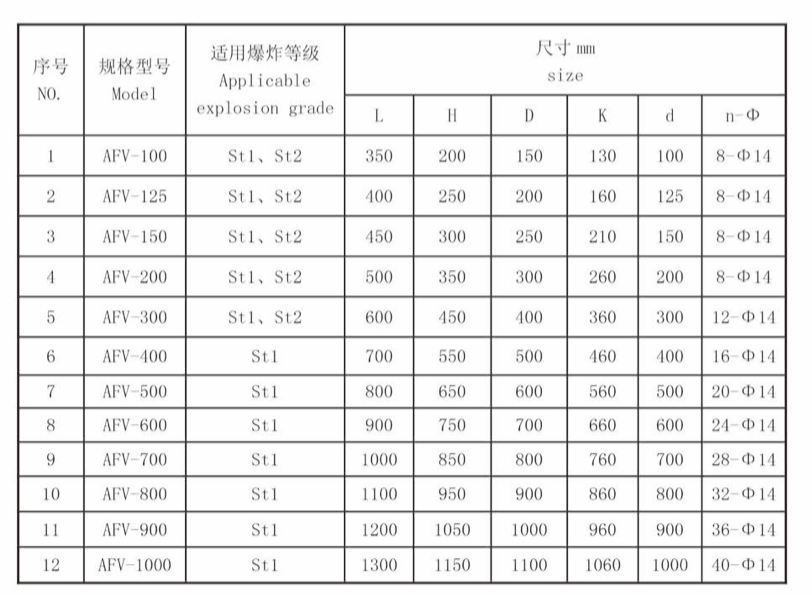

1: Suitable for dust explosion index: St1 and St2, St3 please contact manufacturer;

2: Suitable for dust explosion area: Zone 20, 21, 22;

3: Installation: Horizontal;

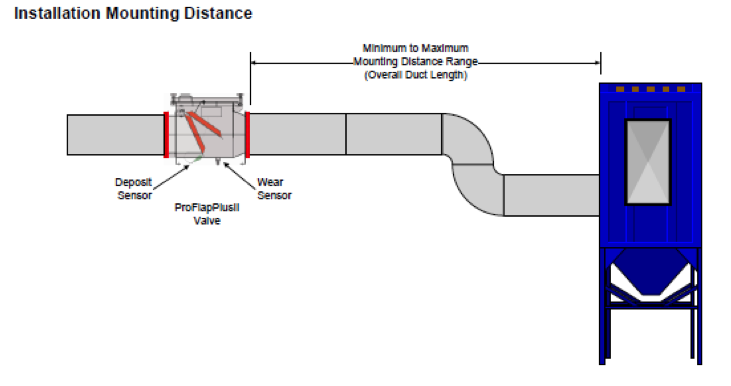

4: Mounting distance; 3-7 meters;

5: Design access door, easy maintenance;

6: Option: disc close alarm device;

7: Used in organic and metal dust, the diameter of flame proof valve is less than DN 700;

8: Meet EN16447-2014 standards;

9: Provide test report of third party authoritative institutions in China

Application

Video

Explosion Dust Example

1: Metal Industry: Magnesium, Titanium, Aluminium;

2: Coal Industry: Activated Carbon, Coal Dust;

3: Synthetic Material Industry: Plastics, Dye Dust;

4: Wood Industry: Paper Dust, Wood Dust;

5: Food Industry: Starch, Flour;

6: Agriculture: Cotton Dust, Tobacco Dust, Suger Dust;

7: Feed Industry: Blood Meal, Fish Meal.