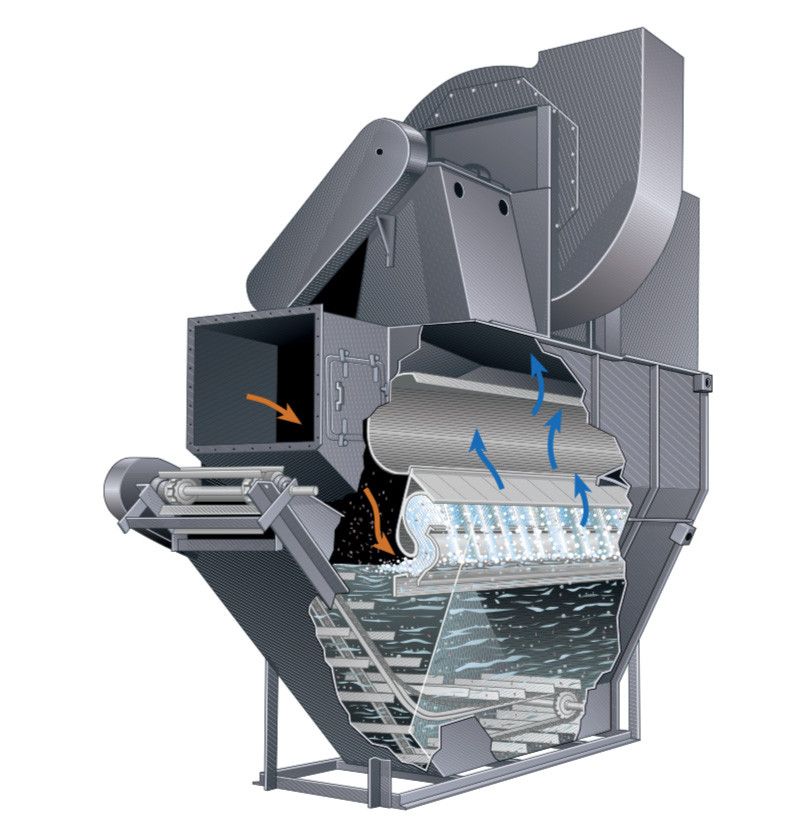

Rotoclone Type Wet Air Scrubber with Automatic Sludge Removal, Wet Gas Scrubber Wet Dust Collector

- Model

- Wet Scrubber Rotoclone

Review

Description

Model | Air volume (m³/h) | Pressure Loss(Pa) | Power (kw) | H (mm) | W (mm) | D (mm) |

Roto clone-1.5C | 2520-3034 | 1500-2000 | 4-5.5 | 3607 | 2308 | 1216 |

Roto clone-2.5C | 4200-5054 | 1500-2000 | 5.5-7.5 | 3607 | 2308 | 1216 |

Roto clone-4C | 6720-8064 | 1500-2000 | 7.5-11 | 3708 | 2308 | 1724 |

Roto clone-6C | 10080-12096 | 1500-2000 | 11-18.5 | 3937 | 2308 | 2257 |

Roto clone-8C | 13440-16128 | 1500-2000 | 18.5-22 | 4861 | 2503 | 2318 |

Roto clone-12C | 20160-24196 | 1500-2000 | 22-37 | 5267 | 3109 | 2318 |

Roto clone-16C | 26880-32256 | 1500-2000 | 37-45 | 5194 | 3755 | 2318 |

Roto clone-20C | 33600-40320 | 1500-2000 | 45-55 | 5194 | 4364 | 2521 |

Roto clone-24C | 40320-48384 | 1500-2000 | 45-55 | 2702 | 4978 | 2521 |

Roto clone-28C | 47040-56448 | 1500-2000 | 55-75 | 2702 | 4978 | 2521 |

Roto clone-32C | 53760-64512 | 1500-2000 | 55-75 | 2702 | 4978 | 2521 |

Roto clone-36C | 60480-72576 | 1500-2000 | 90-110 | 5448 | 6686 | 2521 |

|

Roto clone-40C |

67200-80640 |

1500-2000 |

90-110 |

5601 | 7296 | 2521 |

|

Roto clone-44C |

73920-88704 |

1500-2000 |

110-132 |

5601 | 8011 | 2521 |

|

Roto clone-48C |

88704-93300 |

1500-2000 |

110-132 |

5601 | 8620 | 2521 |