ACMAN Silo Top Sinter Plate Dust Catcher Polyethylene Sheet Filter Dust Collection

- Model

- DF1500

Review

Description

Silo Top Sinter Plate Dust Catcher Polyethylene Sheet Filter Dust Collection

How does sinter plate dust collection machine working?

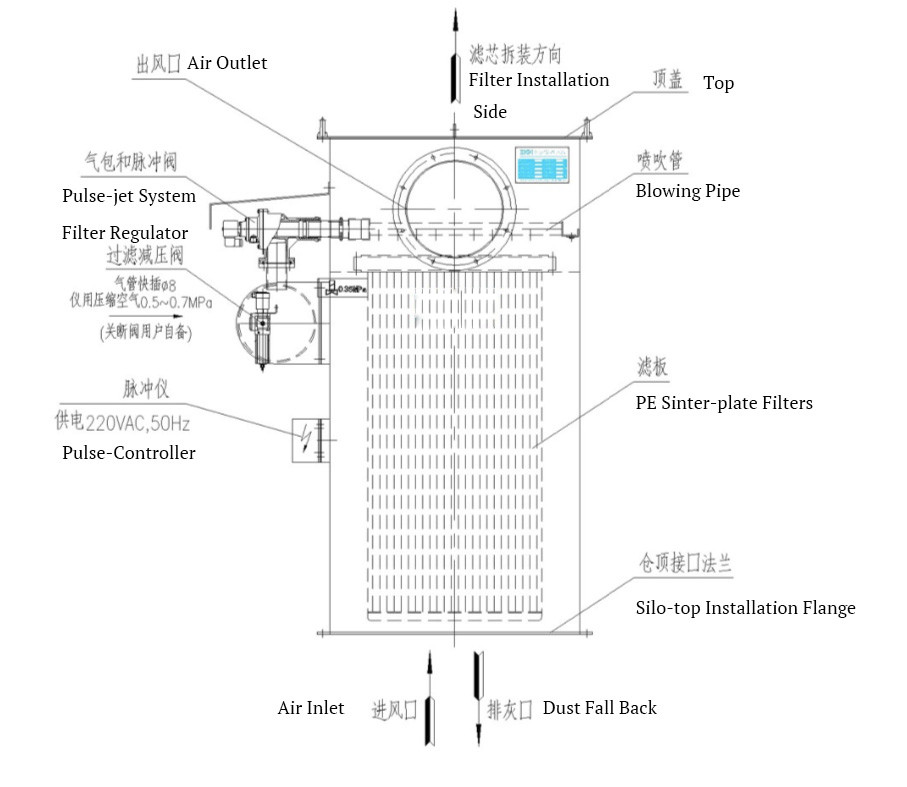

Sinter-plate dust collector

The silo bin vent filter unit is a dust filtration machine on the top of silos or large bins. These storage silos for raw powder and bulk solids materials can be filled by pneumatic conveying systems from bulk tanker or by the bucket elevators . In order to avoid over-pressure in the silo and polluted to the environment, this powder and dust loaded airstream has to be filtration, so the material stays inside the silo and only clean gas exits the filter then emitting to the atmosphere. A fan to support the airflow. The Silotop is a special designed filter for silo venting process. This service-friendly bin vent filter has a pulse jet cleaning system that can be used for a wide range of bulk solids materials.

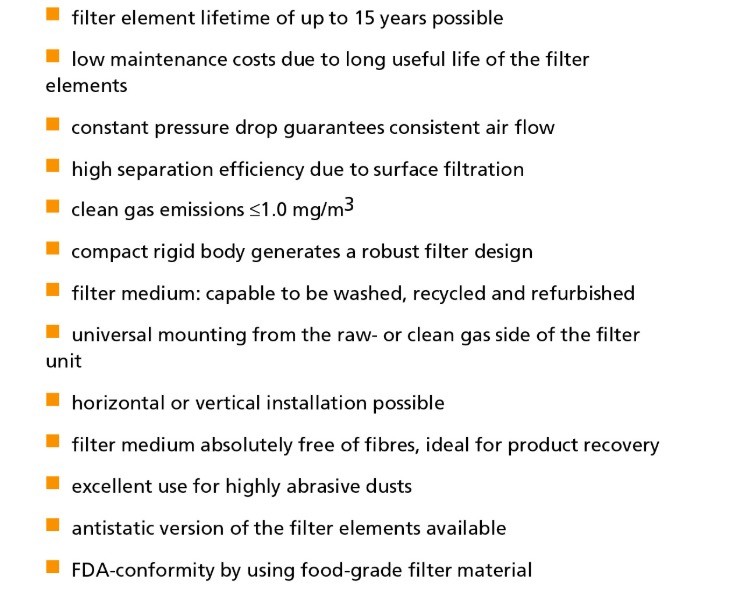

Sinter-plate filter advantages

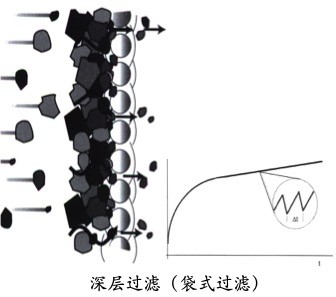

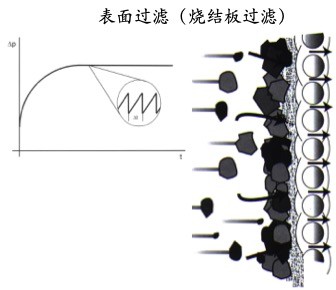

Surface filtration vs Deep filtration

Bag filters/cartridge pleated filters

Traditional filters like bag filter and cartridge filter have high efficiency when the surface dust accumulated, when the pulse-jet working the efficiency will drop, so the pressure is not stable, in some special conditions, it is not suitable.

sinter-plate filters-surface filtration

The sinter plate filter have a PTFE coating on the PE basis, so do not need dust cake to block the other dusts.

when the pulse-jet working, the efficiency will not influenced by the original conditions.

it is called surface filtration.

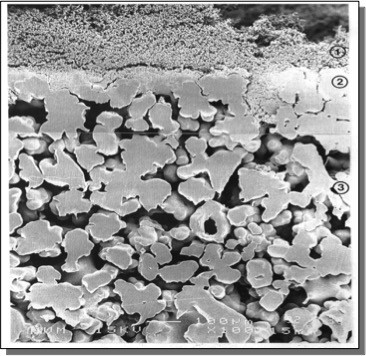

Filter anatomical structure/working principle

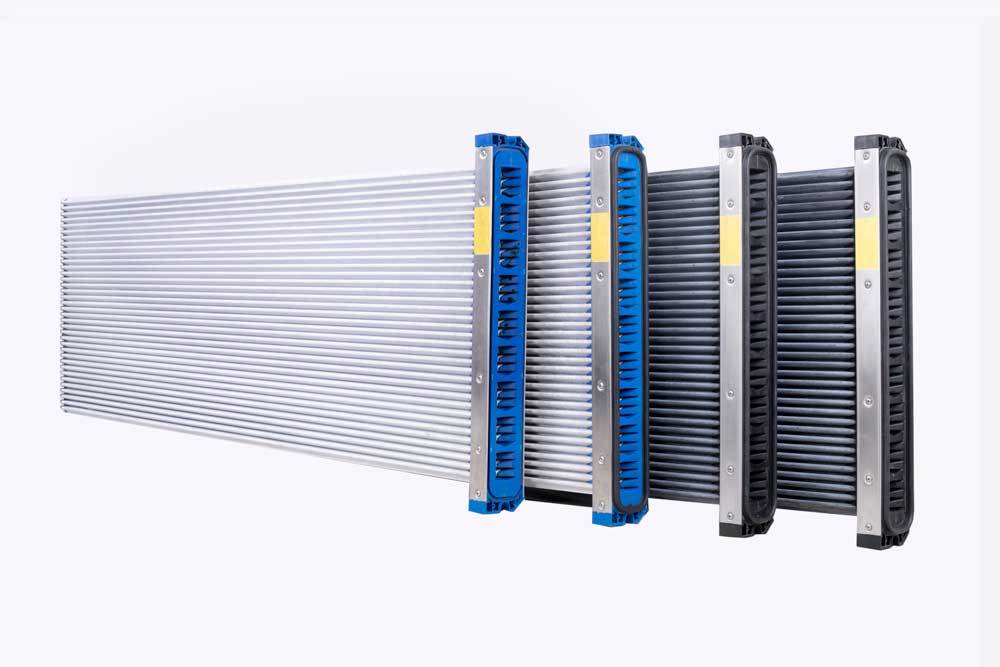

Big filtration area

The plicated design of the sinter-plate filter have big filtration area. our 500*1500mm size filter has 4.75m2.

so the dust collector could design small and that could save lots of space for the company. also, the rigid structure making all the folding area effective.

Sinter-plate inside view

UHMWPE base material: 30um@4mm thick;

PTFE coating: 2-3um@5um thick.

1:Sintered plate dust collector can meet the requirements of users to improve their product quality and improve user productivity.

2:Sintered plate dust collector features long life, maintenance-free and pollution-free, greatly reducing user costs

3:Extremely high filtration accuracy and filtration efficiency, especially suitable for the recovery of ultra-fine powders and high value-added powders

4:The high reliability of the equipment can work for a long time without interruption for a long time, ensuring the interests of users.

5:The overall energy consumption of the equipment is low, and the cleaning gas is returned to the work area as needed, which greatly reduces energy consumption.

6:The equipment is compact in structure, occupying a small space and saving users' land and space resources.

7:Sintered board dust collectors have been widely used and can meet the most stringent requirements for environmental protection in the future.

8:Equipment maintenance is extremely convenient and safe, saving time and effort

9:The equipment can be equipped with fireproof and explosion-proof devices, which Compliance with ISO14001 and food hygiene standards, FDA certification

Customer application

Iron Oxide(8000cmh)

Kaolin Powder Recycle(3000cmh)

Mining Silo(2000cmh)

Lithium iron phosphate

Technical Data

|

Model

|

Airflow

|

Outlet Size

|

Connect Size

|

Filter Area | Weight |

m3/h | mm | mm | m2 | kg | |

VO-BA2 | 188 | 110 | 3.14 | 70 | |

VO-BB2 | 280 | 110 | 4.68 | 80 | |

VO-BA3 | 280 | 110 | 650*460 | 4.71 | 90 |

VO-BB3 | 420 | 160 | 7.02 | 100 | |

VO-BC3 | 570 | 160 | 9.54 | 110 | |

VO-BB4 | 560 | 160 | 9.36 | 135 | |

VO-BC4 | 765 | 160 | 12.72 | 150 | |

VO-BB6 | 840 | 160 | 700*600 | 14.04 | 180 |

VO-BC6 | 1150 | 220 | 19.08 | 200 | |

VO-BD6 | 1710 | 275 | 28.5 | 250 | |

VO-BB8 | 1120 | 220 | 700*750 | 18.72 | 220 |

VO-BC8 | 1530 | 220 | 25.44 | 250 | |

VO-BD8 | 2280 | 275 | 38 | 300 | |

|

VO-BB10

|

1400

|

220

|

700*950 |

23.4 | 260 |

|

VO-BC10

|

1900

|

275

|

31.8 | 300 | |

|

VO-BD10

|

2850

|

330

|

47.5 | 350 |

Videos