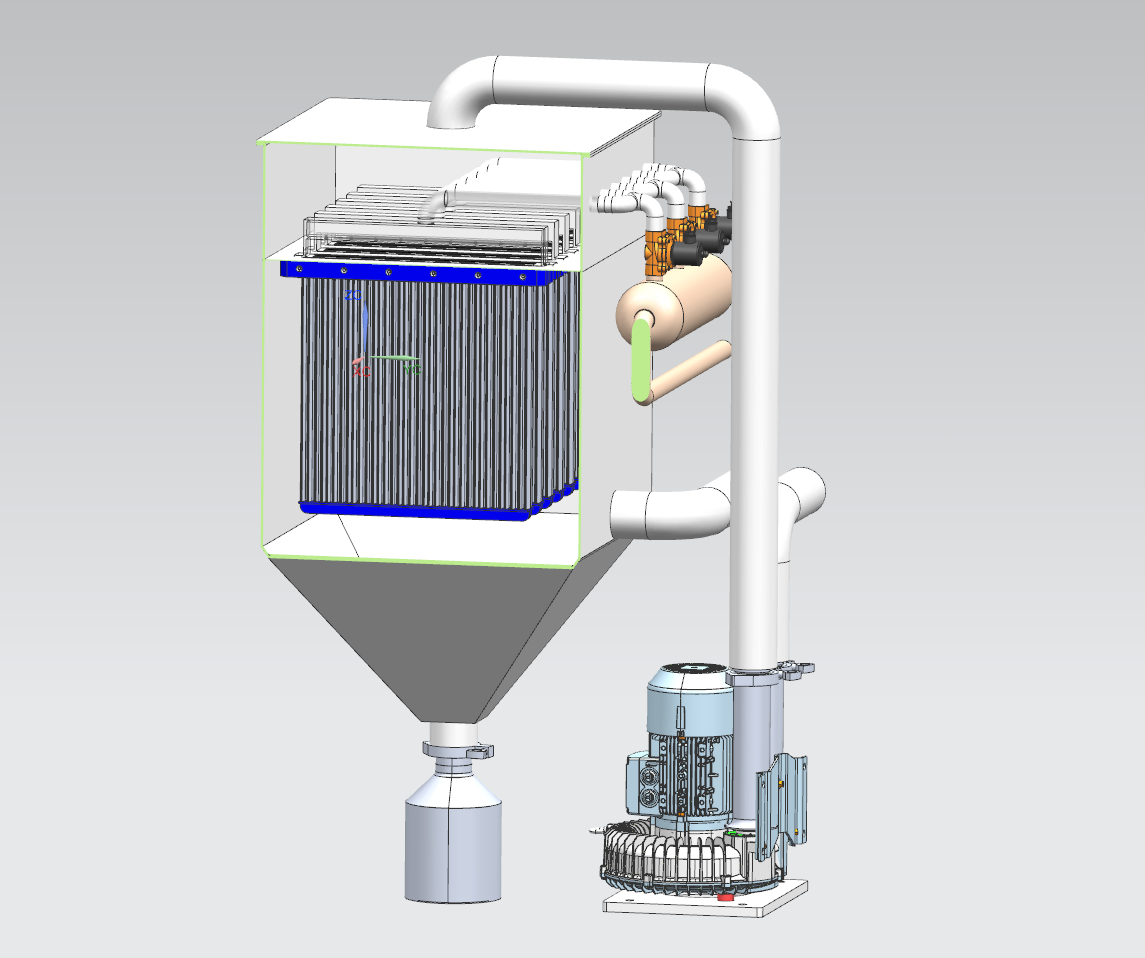

Best Filter for Metal 3D Printer Gas Circulation Filtration System, 3D Printing Atmosphere Filtration System Filter

- Model

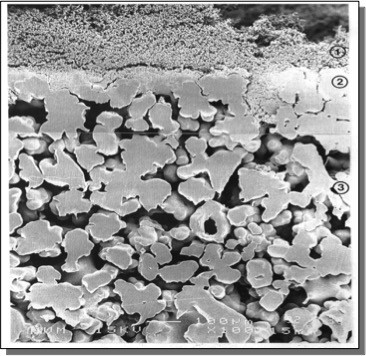

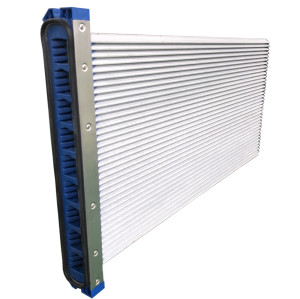

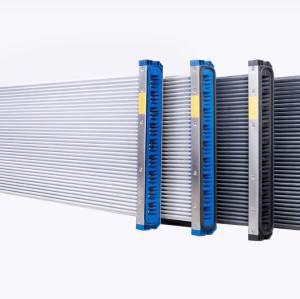

- Delta2 Sinter Plate Filters

Review

Description

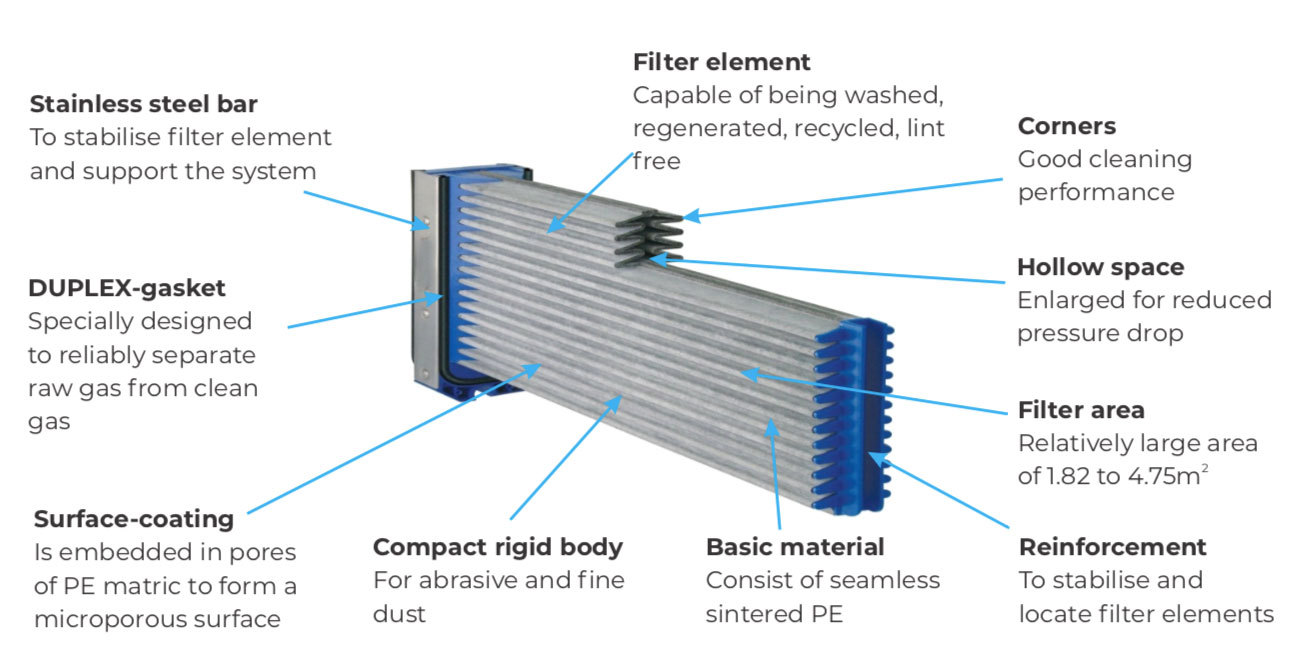

Sinter-plate filter advantage:

l Filter element lifetime of up to 15 years possible

l Low maintenance costs due to long useful life of the filter elements

l Constant pressure drop guarantees consistent air flow

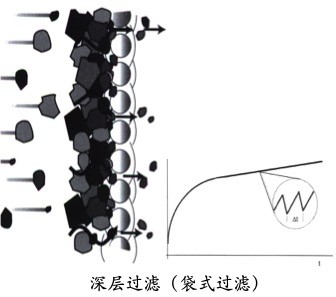

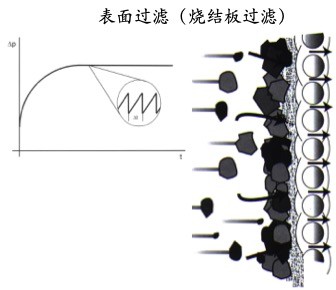

l High separation efficiency due to surface filtration

l Clean gas emissions <1.0 mg/m3

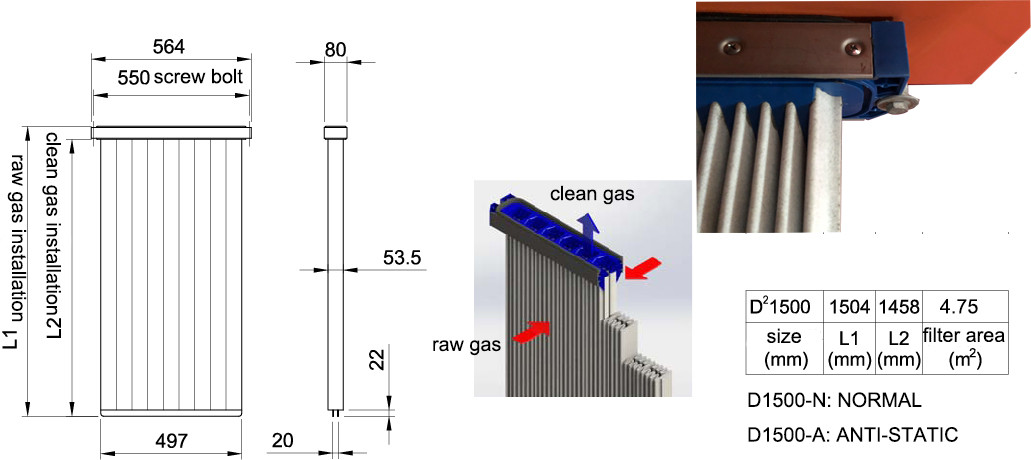

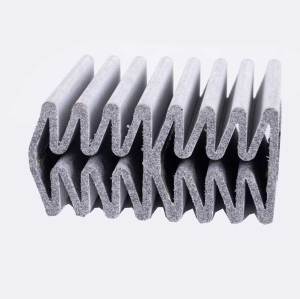

l Compact rigid body generates a robust filter design

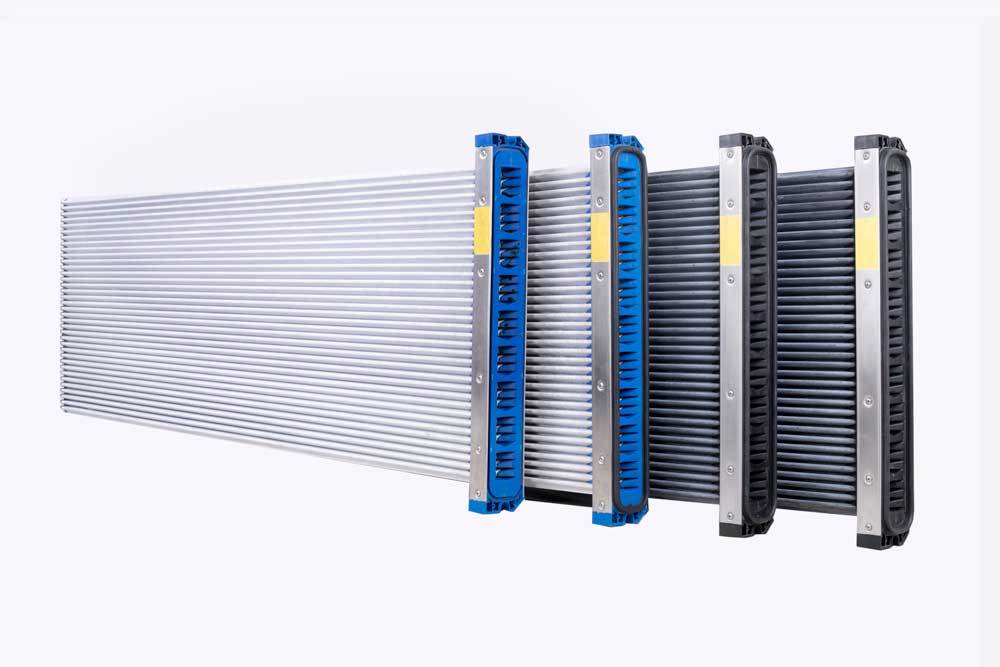

l Filter medium: capable to be washed, recycled and refurbished

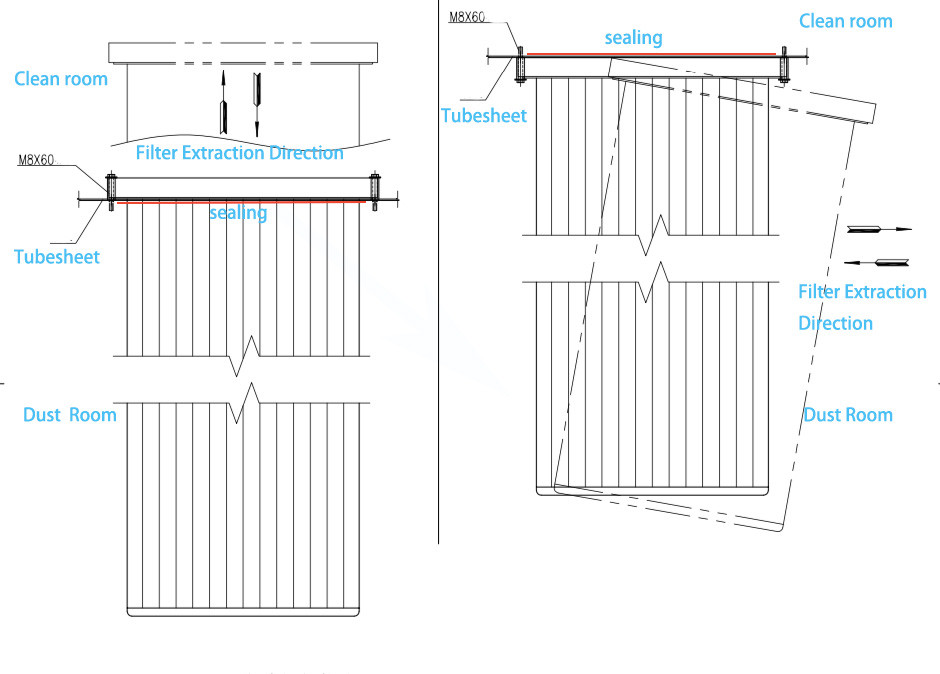

l Universal mounting from the raw- or clean gas side of the filter unit

l Horizontal or vertical installation possible

l Filter medium absolutely free of fibers, ideal for product recovery

l Excellent use for highly abrasive dusts

l Antistatic version of the filter elements available

l FDA-conformity by using food-grade filter material