Jet Dust Collector With Centrifugal Fan, Cartridge Filter Unit with High Pressure for Height Limit Place

- Model

- TR-B-N

Review

Description

Jet Dust Collector With Centrifugal Fan, Cartridge Filter Unit with High Pressure for Height Limit Place

How does this dust extractor working?

This is a title

Professional manufacturer of asphalt machines. Our sales and R&D team have over 10 years’ experience to focus on asphalt distributor, synchronous pavement surface vehicles and other road machinery and equipment. Based on innovation Professional manufacturer of asphalt machines. Our sales and R&D team have over 10 years’

experience to focus on asphalt distributor, synchronous pavement surface vehicles and other road machinery and equipment. Based on innovation synchronous pavement surface vehicles and other road machinery and equipment. Based on innovation

experience to focus on asphalt distributor, synchronous pavement surface vehicles and other road machinery and equipment. Based on innovation synchronous pavement surface vehicles and other road machinery and equipment. Based on innovation

Advantages

Normally, the pulse-jet filters based on vertical design, from top to down side: centrifugal fan, HEPA secondary filters(if necessary), pulse-jet system, cartridge first step filters and dust bin(or dust drawer), but if the install space limit, it do not have to much height for the dust collector machine, or the height is hard for container shipping....

These condition is universally happened in different working process. In addition, the centrifugal fan have multiple choices very from airflow and pressure. so ACMAN could OEM different Jet Pulse Filter Dust Collectors.

This is the pulse-jet cartridge dust collector with fan side placing as an example

Video

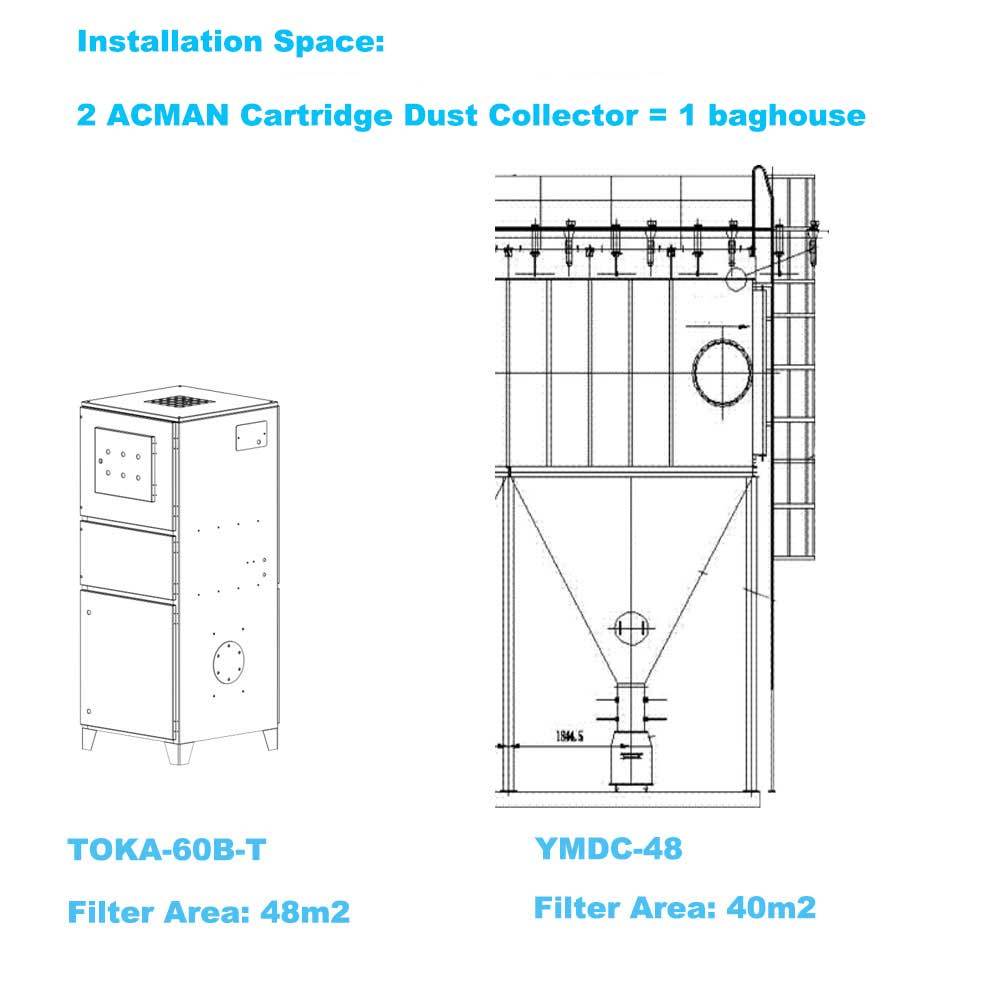

Save Money By Converting to Pleated Filter Dust Collector

converting from traditional bags and cages often brings many benefits:

• Improve Operation – Increase Capacity, Decrease Emissions

• Use Less Compressed Air to Clean Filters

• Pleated Filters Last Longer Than Bags

• Reduce Total Number of Filters in Unit

• Easier Installation – Faster Changeout, Less System Downtime, Lower Labor Costs

• Reduce Filter Abrasion and Lower Grain Loading

• Reduce Inventory – Consolidate Several Different Filters Into One Style

Running cost is sooo low

Item | Unit | ACMAN Pleated Filter Dust Collector | Bag House |

Airflow | m3/h | 10000 | 10000 |

First Investment | USD | Est 12000 | Est 21000 |

Fan Motor Power Consumption | USD/Y | 15kw/h*8h*365days | 15kw/h*8h*365days |

Air Compressor Power Consumption | USD/Y | 30Nm3/h | 90Nm3/h |

Filter Replacement | USD/Y | 1075 | 3320 |

Valve Replacement | USD/Y | 0 | 0 |

Maintenance Labor Cost | USD/Y | 300 | 1500 |

Downtime Cost | USD/Y | 2 Hours | 1 Days Est 2200+ |

3 Year Total Cost | USD | Est 39933 | Est 73669 |

6 Year Total Cost | USD | Est 67866 | Est 126336 |