Stainless Steel Mesh Sintered Filter Elements, Sintered Porous Stainless Steel Filters, SS filter

- Model

- SS-Type

Review

Description

Stainless Steel Mesh Sintered Filter Elements, Sintered Porous Stainless Steel Filters, SS filter

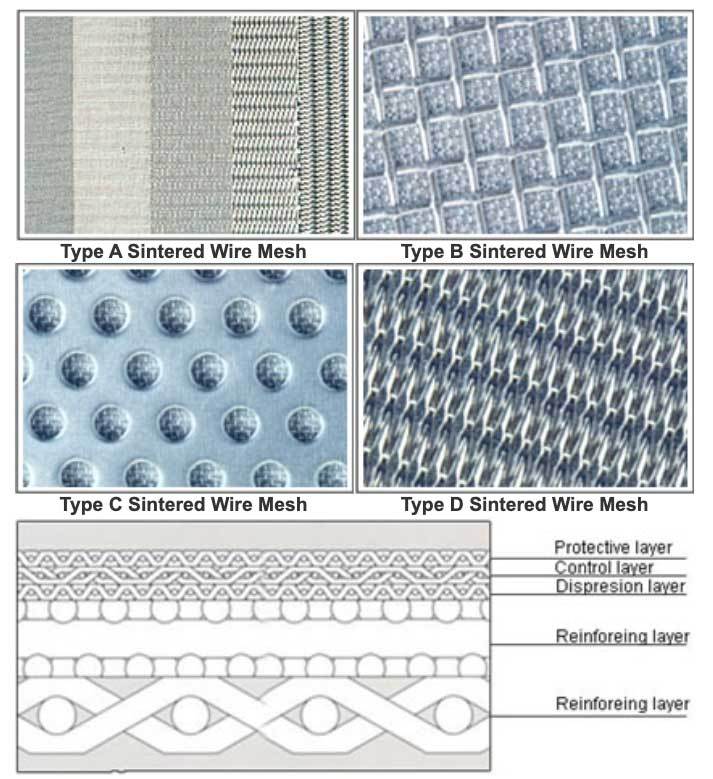

The main point of the stainless steel sintered mesh filter element is that a large number of high-precision welding processes are used. The sintered mesh filter element is welded after rounding treatment. The roundness of the welding part should be ensured. Knotted mesh is a porous sintered material made of stainless steel wire meshes stacked together according to the different structures, and then made by firing, pressing, rolling and other processes. It is generally divided into five layers of structure, namely, protective layer, Filter layer, separation layer, reinforcement layer, support layer five parts. This kind of filter material not only has stable filtering precision, but also has high strength and rigidity. It has high requirements on compressive strength and the filtration mechanism is surface filtration, and the mesh pores are smooth, so it has excellent backwash regeneration performance and can be used repeatedly for a long time, especially suitable for continuous and automated operation. Materials are incomparable.

Advantages

(1) Good strength: due to the support of the fourth and fifth layers, it has extremely high mechanical strength and high pressure resistance.

(2) Easy to clean: Since the surface filter material is used, it has the characteristics of being used for cleaning, and is especially suitable for backwashing.

(3) Easy processing: suitable for cutting, bending, stamping, stretching, welding and other processing techniques.

(4) High temperature resistance: can withstand high temperature of 600 ℃.

(5) Corrosion resistance: Since SU316L and 304 materials are used, the corrosion resistance is strong.

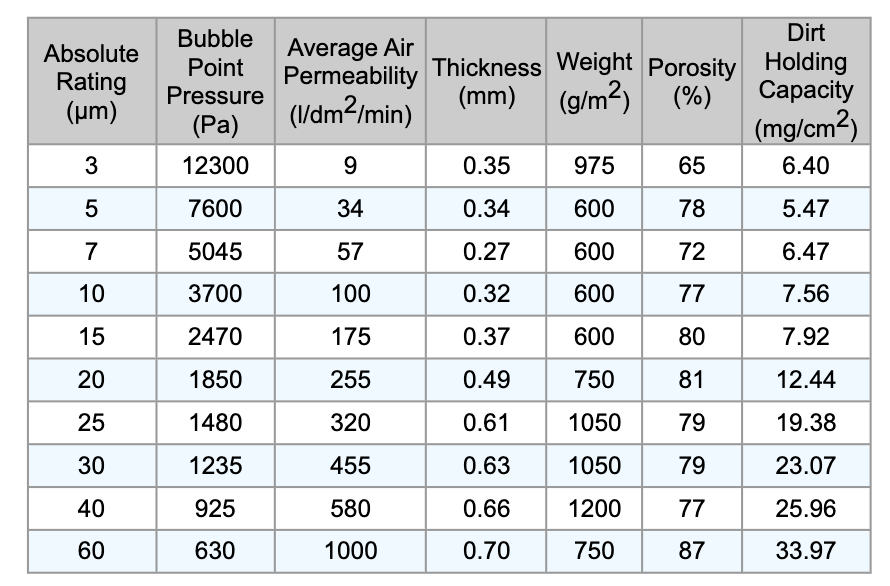

(6) Filtration precision: The range of filtration precision is 1um-200um, with reliable filtration performance.

(7) Stability: Due to the protection of the upper and lower layers of wire, the filter screen is not easily deformed by the sintering process of diffusion solid melting.

Installation

1. Standard interface (222/220/226)

2. Fast interface connection

3. Threaded connection (internal thread, external thread)

4. Flange connection

5. Tie rod connection

6. Special custom connection

Application

(1) Materials used for dispersion cooling in extremely high temperature environments

(2) It is used for the application of uniform gas in the powder industry, and the fluidized plate in the iron and steel industry.

(3) Orifice plate material for gas distribution fluidized bed

(4) It is used for blast furnace spraying pulverized coal flow and dense phase conveying system

(5) Filtration, washing and drying of materials in the pharmaceutical industry

(6) Catalyst support barrier

(7) For polyester and oil products. Food-grade beverages, filtration of chemical fiber products, also used for water treatment and gas filtration.

Technical Data

Video